Have you ever experienced the frustration of waking up in the middle of the night, only to find that your air mattress has mysteriously and deflated? Well, you’re not alone! In this article, we will explore the possible reasons behind the sudden deflation of an air mattress. From tiny punctures to temperature changes, we will uncover the common culprits that could be causing your once-comfortable sleep vessel to become a floppy disappointment. So, if you’re tired of waking up with a deflated air mattress, keep reading to find out what might be causing this annoying phenomenon.

Review contents

I. External Factors

A. Sharp objects

One of the external factors that can cause an air mattress to suddenly deflate is the presence of sharp objects. It is important to keep the mattress away from any sharp objects such as scissors, knives, or even sharp edges of furniture. Accidental contact with these objects can result in punctures or tears in the mattress, causing it to lose air and deflate.

B. Punctures

Another external factor that can lead to the deflation of an air mattress is punctures. Punctures can occur due to various reasons, such as stepping on the mattress with shoes on, having pets with sharp claws near the mattress, or even accidentally dropping sharp objects onto the mattress surface. Even small punctures can result in air leakage, gradually causing the mattress to deflate.

C. Extreme temperature changes

Extreme temperature changes can also have an impact on the air pressure and overall stability of an air mattress. When exposed to high temperatures, the air inside the mattress expands, leading to increased pressure. On the other hand, when the mattress is exposed to cold temperatures, the air inside contracts, causing a decrease in pressure. These fluctuations in air pressure can lead to the sudden deflation of the mattress if not properly managed.

II. Internal Factors

A. Valve leakage

Valve leakage is one of the internal factors that can cause an air mattress to deflate unexpectedly. The valve is responsible for controlling the flow of air in and out of the mattress. If there is a defect or damage in the valve, it can result in air leakage and subsequent deflation of the mattress. It is important to regularly check the valve for any signs of leakage or damage and promptly address any issues to ensure the optimal performance of the air mattress.

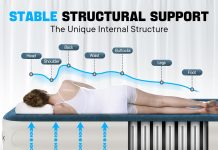

B. Seams coming apart

The seams of an air mattress play a crucial role in maintaining its structural integrity and preventing air leakage. However, over time, the seams may start to come apart due to wear and tear or poor quality stitching. When the seams come apart, the mattress loses its ability to hold the air inside, leading to gradual deflation. Regular inspection of the seams and timely repairs or replacements can help prevent this issue.

C. Fabric degradation

The fabric used in air mattresses can degrade over time, especially if it is exposed to harsh conditions or subjected to excessive wear and tear. Continuous use, exposure to sunlight, and contact with chemicals or rough surfaces can weaken the fabric, making it more prone to tears and punctures. As the fabric deteriorates, it becomes easier for air to escape, resulting in the gradual deflation of the mattress. Proper care and maintenance, such as regular cleaning and storing the mattress in a suitable environment, can help prolong its lifespan and prevent fabric degradation.

III. User Habits

A. Overinflation

Overinflation is a common user habit that can lead to the sudden deflation of an air mattress. Some individuals may inflate the mattress beyond its recommended capacity, thinking that it will provide more comfort or support. However, overinflation puts excessive pressure on the mattress, causing stress on the seams and increasing the risk of air leakage. Following the manufacturer’s guidelines and not exceeding the recommended inflation level can help prevent overinflation-related deflation.

B. Rough handling

Rough handling of an air mattress can also contribute to its deflation. Tossing the mattress around, jumping on it, or placing heavy objects on top of it can apply unnecessary strain on the seams and fabric, leading to damage and air leakage. It is important to handle the mattress with care, avoiding any rough or sudden movements that could potentially cause harm. By treating the mattress gently, users can minimize the risk of sudden deflation.

C. Wrong storage

Improper storage of an air mattress is another user habit that can result in unexpected deflation. Folding or storing the mattress in a way that exposes it to sharp objects or excessive pressure can lead to punctures or damage to the valve and seams. It is recommended to store the mattress in a clean and dry place, away from any potential hazards. Folding it carefully and using a protective bag or cover can further safeguard it against external factors that may cause deflation.

IV. Manufacturing Defects

A. Poor quality control

Manufacturing defects can also contribute to the sudden deflation of an air mattress. Poor quality control during the manufacturing process can result in subpar materials, improperly sealed seams, or faulty valves. These defects may not be immediately apparent, but they can eventually lead to air leakage and deflation. Choosing a reputable brand known for its stringent quality control measures can help reduce the risk of manufacturing-related deflation issues.

B. Faulty materials

The quality of materials used in an air mattress plays a crucial role in its long-term durability and resistance to deflation. If the materials are of low quality or not suited for the intended purpose, they may deteriorate quickly, leading to punctures, valve defects, or fabric degradation. Investing in a high-quality air mattress, preferably made with durable and reliable materials, can significantly reduce the chances of sudden deflation due to faulty materials.

C. Improper sealing

Proper sealing of seams and valves is essential to maintain the air-tightness of an air mattress. If the sealing process during manufacturing is not done correctly, it can result in weak spots that are prone to air leakage. Over time, these weak spots can develop into larger openings, causing the mattress to deflate. Manufacturers that prioritize meticulous sealing techniques and rigorous quality checks can ensure that their air mattresses are less susceptible to deflation due to improper sealing.

V. Air Pump Issues

A. Valve connection problems

Air pump issues can also contribute to the deflation of an air mattress. One common problem is valve connection issues. If the air pump’s nozzle or the mattress’s valve is damaged, loose, or incompatible, it may result in a poor connection, leading to air leakage during inflation or deflation. Ensuring that the valve and pump nozzle are clean, undamaged, and properly matched can help maintain a secure connection and prevent air loss.

B. Air leakage during inflation

During the inflation process, air leakage can occur if there are any leaks in the mattress or the pump’s hose. Even a small leak can compromise the inflation process and result in a partially or fully deflated mattress. Regularly inspecting the mattress for punctures, tears, or faulty seams, and ensuring the pump’s hose is intact can help prevent air leakage during inflation and ensure the mattress remains properly inflated.

C. Air loss during deflation

Similar to inflation, air loss can also occur during the deflation process if there are any leaks in the mattress or the pump’s valve. If the valve is not tightly closed or if there are defects in the mattress that allow air to escape during deflation, the mattress may not fully deflate or lose air gradually. Checking the valve’s condition and ensuring it is properly sealed, along with inspecting the mattress for any possible leaks, can help minimize air loss during deflation and ensure the mattress can be properly stored.